Mo Wuwei: The Red Alert 2 Fan Who Automated Carbon Capture Testing

At a climate-tech start-up in California, a fully automated carbon capture testing system is running around the clock, steadily improving research efficiency. Behind this system is Mo Wuwei, a Class of 2024 graduate of Xiamen University Malaysia, whose journey from university research to industry innovation reflects the impact of hands-on engineering education.

By Yulin Wu

Turning curiosity into an engineering path

Wuwei’s interest in engineering began in his childhood. He was fascinated by children described in European and American TV series. They could conduct experiments and DIY creative stuff in their own garages using simple equipment. From an early age, he hoped to have a hands-on space of his own. This interest led him to pursue engineering as his academic path.

Through frequent exposure to articles on climate change and environmental protection, Wuwei developed a desire to use his knowledge to improve the environment. In 2018, he enrolled in the Bachelor of Chemical Engineering with Honours programme at the School of Energy and Chemical Engineering (SECE), Xiamen University Malaysia (XMUM).

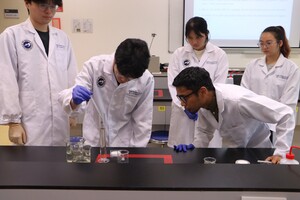

In his third year, Wuwei learned that Dr. Ong Wee Jun’s research focused on nanotechnology and renewable energy. He contacted Dr. Ong to express his passion for environmental sustainability. Dr. Ong assigned him two research topics: Electrocatalysts for hydrogen evolution and CO2 reduction.

“Working on electrocatalysis helped me connect abstract concepts to the bigger picture of climate change mitigation,” Wuwei says. “It set the direction for my future career.”

Depth Learning in UC Berkeley

While applying for his Master’s degree, Wuwei received offers from many renowned universities. In the end, he chose Materials Science and Engineering Programme in Berkeley.

The coursework in materials science at Berkeley is highly rigorous and cutting-edge in design. For Wuwei, who did not have a background in materials science, it was difficult to fully follow the classes at the beginning.

One course named Advanced Spectroscopy left a particularly strong impression on him. The course combined advanced spectroscopy in materials science with Python programming. Students were not only required to understand the working principles of different spectroscopic instruments, but also to write code to analyse raw experimental data.

For completing the assignments better, Wuwei and his classmates formed a study group. “Most of us were complete beginners in programming, so we learned through trial and error. We constantly exchanged ideas, discussed problems, and helped each other debug our code,” he said, “When we finally produced clean, well-visualised spectra, the sense of accomplishment was incredibly rewarding”.

For his Capstone Project, Wuwei focused on investigating various trending solid sorbents used for direct air capture. Thanks to his undergraduate research experience, Wuwei was very familiar with this area, which made the project easier for him to approach. In addition, the software skills and programming logic he acquired through coursework and the Capstone Project laid a solid foundation for his later system development and his understanding of electrical engineering and automation.

Automating carbon capture in the lab

Upon completing his Master’s degree in Materials Science and Engineering at UC Berkeley, Wuwei joined Mitico as an R&D Intern, but was soon promoted as an R&D Technician. The company develops environmentally friendly solid sorbents for carbon capture, which matches the interests he had since undergraduate years.

He was mainly responsible for testing solid sorbents, data collection and analysis, as well as designing automated experimental systems based on client requirements. As a startup, Mitico offered many chances to build things from scratch. The working structure was flexible, and employees were not limited to their own job descriptions. This experience also helped lay the groundwork for Wuwei’s later learning in electrical engineering and automation.

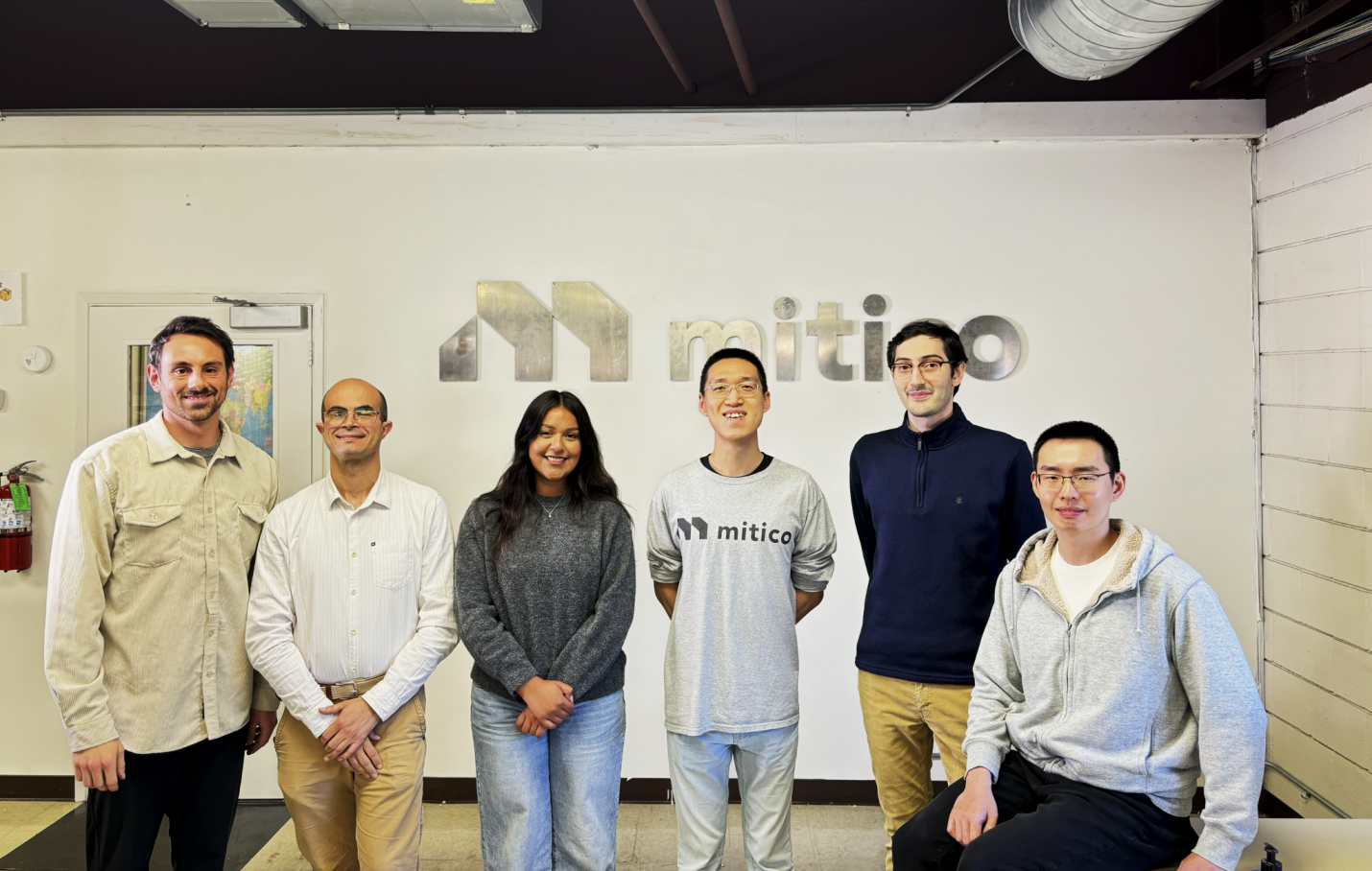

Mo Wuwei with his colleagues at Mitico

“Our CTO, Alan Gu, is my model.” Wuwei joked. At the time, Mitico designed the very first carbon capture system and commissioned a supplier to manufacture the equipment. During operation, the system required continuous modifications and optimizations from the supplier’s end. Repeatedly requesting the supplier to perform remote adjustments proved inefficient. As a result, Alan taught himself the necessary software operation and programming.

This experience inspired Wuwei. “He let me know that a true engineer should not be limited to their own field. Engineering is inherently interdisciplinary.”

The idea for the automated testing system came from a practical bottleneck in sorbent development. Wuwei was in charge of testing the sorbents, which involved repeated cycles of absorption and regeneration. Manual testing was highly inefficient, taking a whole day for just one cycle, and often consumed all of his time, leaving little room for other work. He realized that a fully automated system was necessary to overcome this problem.

He drew inspiration from the mobile construction vehicle in Command & Conquer: Red Alert 2. “A mobile construction vehicle can transform from a small truck into a massive structure within seconds, and vice versa, which is highly mobile and convenient. This is impossible in reality. However, I thought I might be able to design a convenient system. With only the most basic equipment, electricity, and gas, it could be deployed anywhere.”

He set out general milestones for the project. The first step was to connect the different pieces of equipment to a computer to enable data transfer, which required him to learn electrical engineering and automation on his own. At the beginning, it was like feeling around in the dark, He had no basic knowledge or understanding of the principles and had to go through instrument manuals line by line. He also asked technical staff from the suppliers for help, but without a solid background, he could only understand bits. At one point, he almost considered spending $100 on a single data cable from them. Looking back now, he could have made it by hand for just a few dollars.

Fortunately, with the help of AI, he was able to understand what to do in plain, non-technical language, and gradually learned the basic concepts. Eventually, he took roughly nine months to figure everything out: half a year for controlling and monitoring of each equipment from the computer, about a month and a half learning and programming to create the control software, another month assembling the hardware, and half a month testing the system.

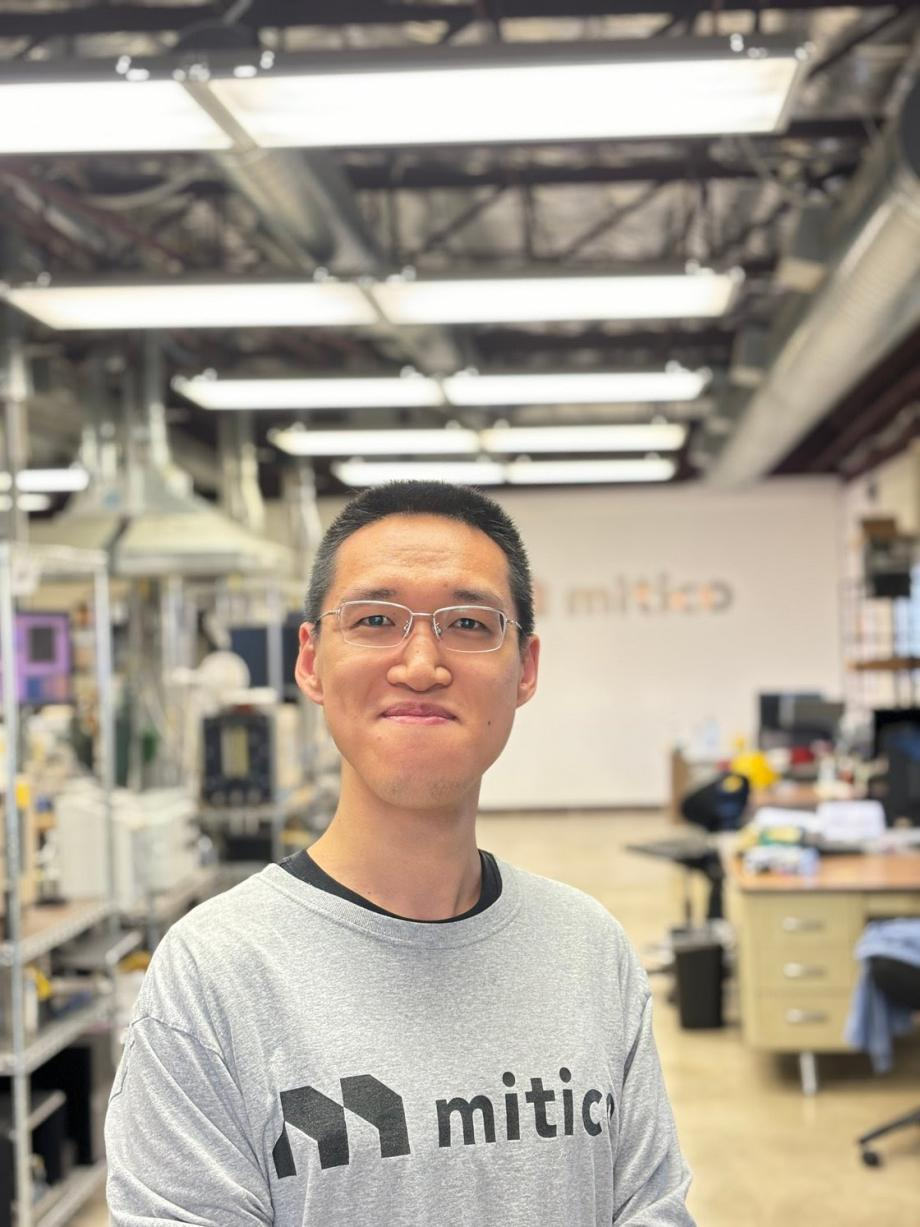

In May 2025, when the first prototype was completed, he felt proud and excited. “I told my colleagues that I had succeeded. Everyone was thrilled, and they said I was a legend.” He named the six stations after his favorite units from the game. The automated system now runs 24/7, increasing testing capacity by up to 2400% and speeding up the department’s R&D progress.

Mo Wuwei with the cycling stations

At present, Wuwei appears to be one step closer to his childhood dream of changing the world through hands-on work. However, he is not satisfied. “As an engineer, I still have much to learn,” he said. Chemical engineering should not exist as an isolated discipline. It must be integrated with other fields of expertise. Whether for career development or personal growth, Wuwei has no intention of stopping here.